Export plays a big part of our business at Lifting Equipment Store, we export large quantities of lifting equipment every month to various repeat customers around the globe.

One of the things I have commonly experienced when ordering goods from abroad is that the suppliers do not package their pallets securely. This can lead to damaged goods and even missing goods, not ensuring your goods could cost you more than you expect and even if you do insure them if they are not packed correctly some insurance policies will be void. Even when you order UK to UK the packaging would not suffice any longer than overnight.

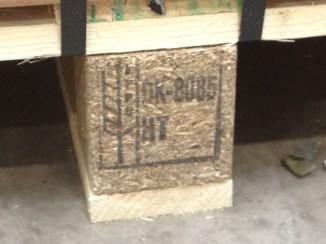

This is where we come in, before goods are shipped abroad when purchased from us we ensure that our export consignments are re-packed in suitable containers for export featuring tripple thick cardboard (or wooden containers), ISPM 15 Heat treated pallets (metal is also optional), All packing is re-enforced and wrapped. Then the boxes (or box) is banded and strapped to the pallet to ensure full security, after that the box/container is wrapped for extra protection and security.

We go the extra mile and ensure that your consignment is fully labelled and accompanied with the correct documentation: Packing list, Commercial Invoice, Certificate of Origin, Etc.

Check out how we packed this consignment of Lifting Equipment below. In this we have 80 x Container Lifting Lugs (2 layers), 20 x 7 Tonne Bow Shackles (1 layer), 20 x 7 Tonne Dee Shackles (1 Layer), 10 x Yale height safety kits with carrying cases (1 layer and extra two boxes on top). Weighing in at just over 1000kg (1 Tonne). It’s like wrapping a giant Lifting Equipment Christmas present!!….

Camlok Container Lifting Lugs for Export to the Middle East

Required for customs clearance in most countries now. Heat treated pallets ensure no wood contaminations make it into foreign countries.

Fully banded and wrapped to support all sides and secure the load together, just to be labelled and relevant documentation attached. Total weight just over 1000kg (1 Tonne).